Project name: Jiangsu Taicang Ocean Logistics Carbon Dioxide Cold Chain Engineering Project

Project Location:Taicang, Jiangsu

Project Scale:80000m³

Project Introduction:

The project is located in Shaxi Town, Taicang City, just 30 minutes from the city center. It is adjacent to the Shenhai Expressway and within a one-hour drive of several major transportation hubs, including Suzhou, Kunshan, and Shanghai. The location offers significant regional advantages. The project consists of two high-standard warehouses with dual-sided, dual-layer ramps. This project is the first batch of carbon dioxide cascade refrigeration system cold storage in China, using natural environmentally friendly refrigerants. This project is a variable temperature storage, divided into 6 rooms, using 0-4℃、-18℃can be automatically switched according to actual needs, and the platform maintains a constant temperature of 10℃.

Project Name: Hunan Changsha Yupei Group Cold Chain Logistics Park Cold Storage Engineering Project

Project Location: Changsha

Project scale: 62655m³

Project introduction:

Yupei Changsha High-Tech Zone Logistics Park features 120,000 square meters of high-standard Class B warehouses and includes a 10,000 square meter cold storage facility. It is a landmark cold chain logistics park in Hunan Province. Design Temperature: -18~-25℃、0-10℃。 Refrigeration Method: Environmentally friendly fluorine-based refrigerant with barrel pump liquid supply system.

Project Name: Xinjiang Yining Bonded Zone Cold Chain Logistics Park Cold Storage Project

Project location: Yining, Xinjiang

Project scale: 78525m³

Project introduction:

This project is a large-scale cold chain engineering facility for agricultural products and food import-export trade logistics. It provides low-temperature storage environments for various types of food. It is primarily used for storing meat, food products, and other goods. The facility is equipped with a comprehensive food cold chain system to ensure proper storage and transportation of the products. The design temperature requires -22℃~-4℃,Freon refrigeration, barrel pump liquid supply method. The warehouse is equipped with an intelligent management system for better management.

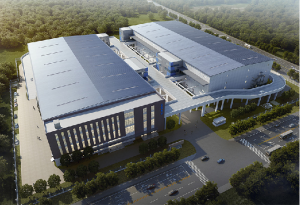

Project Name: Chengdu Qingbaijiang Railway Port Logistics Park Comprehensive Bonded Logistics Project

Project Location: Chengdu, Sichuan

Project scale: 50000m³

Project introduction:

The core construction content of the China Western Railway Logistics Center project is based on the construction of the Chengdu Railway Container Center Station, which is the largest in Asia, and the Chengdu Railway Port China Customs Inspection and Quarantine designated imported meat cold storage. The overall 5,000-ton meat freezer adopts imported joint venture brand cold storage equipment. The temperature design is -18℃~-25℃,environmentally friendly Freon refrigeration, and barrel pump liquid supply method.

Project Name: Guannan JD E-commerce Cold Chain Logistics Park Cold Storage Project

Project location: Lianyungang, Jiangsu

Project scale: 35000m³

Project introduction:

JD e-commerce large cold chain logistics industrial park cold chain project, the project is mainly used for fresh, meat, vegetables, food storage and distribution. Covering a variety of storage temperature zones, mainly divided into 3000㎡ freezer(-18~-25℃)、1# cold storage 1860㎡(0~10℃)、2# cold storage 1860㎡(0~10℃)、platform 860㎡(8~15℃ ). Adopt one-for-one equipment configuration standard, electric defrosting. Environmentally friendly Freon refrigeration, barrel pump liquid supply method.

Project name: Hema Fresh Fresh Distribution Cold Chain Logistics Park Cold Storage Project

Project location: Hangzhou, Zhejiang

Project scale: 47408m³

Project introduction:

Large-scale fresh e-commerce distribution logistics industrial park, mainly used for fresh fruits and vegetables, food storage and distribution, radiating surrounding areas, providing regional distribution of fresh food and agricultural products. Covering a variety of storage temperature zones, meeting a variety of temperature standards such as 0~4℃、0~10℃、8~12℃ . Environmentally friendly Freon refrigeration, barrel pump liquid supply method.

Project name: Xuzhou Tianyi Aquatic Cold Chain Market Cold Chain Project

Project location: Xuzhou, Jiangsu

Project scale: 22216m³

Project introduction:

Xuzhou Tianyi Aquatic Market Cold Chain Project is a typical market trading cold storage at the municipal level. It has a superior geographical location and convenient transportation, and supplies aquatic seafood and other products to the surrounding markets. The total area of the cold storage is 2900 square meters, divided into three rooms, 1# ice storage(-5~-10℃)covers an area of 217 square meters; 4.5m high; 2# low temperature through-hall storage(10~15℃)covers an area of 180 square meters and is 6m high; 3# low temperature freezer(-18~23℃)covers an area of 2520 square meters and is 8m high. Environmentally friendly Freon refrigeration, barrel pump liquid supply method. The cold storage passed the one-time acceptance, and all equipment has been operating normally since its use.

Project name: China Supply and Marketing (Pingxiang) Agricultural Products Logistics Park Cold Chain Project

Project location: Pingxiang, Jiangxi

Project scale: 97800m³

Project introduction:

The cold chain project is based in Pingxiang City, covers the western Jiangxi region, serves the Changsha-Zhuzhou-Tanzhou region, and connects the whole country. The project follows the functional model of transaction + e-commerce + finance + cold chain logistics + warehousing and distribution + inspection and testing. It is a typical one-stop agricultural and sideline products distribution center with rich categories, complete functions and complete supporting facilities, and a modern agricultural-related trade comprehensive service platform. This project is divided into three floors, the first floor: 0~5℃ fresh-keeping warehouse, the second floor, half of which is 0~5℃ fresh-keeping warehouse, and the other half is variable temperature warehouse 0~5℃/-18~-23℃,and the third floor: -18~-22℃freezer (aluminum row warehouse). Adopt imported refrigeration centralized control system, reasonably control compression volume, high efficiency and energy saving; diversified temperature control technology, precise temperature control, stable warehouse temperature; each warehouse has gas parameter recording and curve analysis functions; environmentally friendly Freon refrigeration, barrel pump liquid supply method.

Project name: Huzhou Lianmei Agricultural Fruit and Vegetable Origin Type Air Conditioning Cold Storage Project

Project location: Huzhou, Zhejiang

Project scale: 16000m³

Project introduction:

Mainly for ecological leisure agricultural planting, sales and sightseeing, the cold storage is completed and is expected to store 4,000 tons of “Red Beauty” citrus, which can be kept fresh for up to 5 months. Borrowing cold storage and contacting downstream sales channels to form a complete industrial system of “planting base + sightseeing agriculture + agricultural product storage and sales”. The project includes 8500m³ air-conditioned cold storage (divided into 13 rooms), 3500m³freezer (divided into 3 rooms) and 4000m³ pre-cooling buffer areas such as halls and platforms. The air conditioning system of the cold storage adopts CAF, including deoxygenation nitrogen generator and carbon dioxide removal machine (200KgCO2/24 hours, at 3% concentration). Temperature requirements: 2~-8℃、-2~0℃、10~15℃。 Refrigeration method: Freon refrigeration, barrel pump liquid supply method.

Project name: Sichuan Liangshan Yanyuan County Serving the Three Rural Areas Gas Conditioning Storage Project

Project location: Sichuan Liangshan

Project scale: 3888m³

Project introduction:

This fruit and vegetable production area cold storage mainly serves the development of “three rural areas” and is used to store local specialty agricultural and sideline products. The cold storage has a total of 18 rooms, using an imported centralized control system, which automatically adjusts the energy steplessly according to the heat load in the storage, and reasonably controls the compression volume, so as to achieve the purpose of high efficiency and energy saving. Using diversified temperature control technology, the temperature control is accurate and the storage temperature is stable. The gas conditioning equipment has automatic gas concentration analysis, automatic deoxygenation, automatic humidity control, automatic removal of carbon dioxide, and has the function of recording gas parameters and curve analysis in each warehouse. The temperature requirement is 0-5℃;it uses environmentally friendly Freon refrigeration and direct expansion liquid supply.

Howcool Refrigeration

Specializing in providing technical services of cold chain logistics project design , engineering cost, engineering drawings.

Whatsapp:+86-15510514643